Download ASSDA Technical FAQ 5 (PDF)

WHAT IS GALLING?

Austenitic stainless steels are widely used for corrosion resistant bolting. One of the major problems in use is that diassembly is difficult because nuts and bolts seize. This phenomenon is known as galling and it is most prevalent with intermittently operated, slowly sliding surfaces. It is caused by cold welding of the high points of clean, oxide-free metal left when the oxide film is dislodged by surfaces rubbing against each other. In high temperature service, there may also be a contribution from oxidation forming abrasive oxides and also reducing clearances. Diffusion bonding of the metal is also possible during long-term exposure but is not as likely to cause problems at reasonable temperatures.

Titanium and aluminium also suffer from galling. Specialist literature suggests that anodising or lubrication are both effective remedies. Anodising of stainless steel, however, is not regarded as a remedy since the chromium oxide film is orders of magnitude thinner than the oxide film on titanium or aluminium.

HOW TO CONTROL GALLING

The measures listed are roughly in order of importance and are explained in the next section.

- Hardness: Ensure a hardness difference of at least 50 Brinell between the but and bolt.

- Design and quality control: Confirm that the mechanical fit is correct, the surfaces are smooth but not mirror like, and that they are clean.

- Reduce friction: Select an appropriate lubricant and/or substrate material. Lubrication is required even if the joint is intended to be permanent.

- Control: Use a torque wrench and the correct force for the material class and surface conditions.

THE DETAILS

Surface Hardness

Surfaces treated so that they are harder, for example, hard chrome plated, nitrided, carburised or cold worked surfaces are usually less susceptible to galling.

However, the corrosion resistance of nitrided or carburised surfaces is less than standard pickled and passivated stainless steel. Hard chromium electroplated coatings (3 μm to 0.5 mm) are not recommended for high temperature or high stress service as they may crack and spall.

A shot peened (and hence cold worked) surface would not normally be suitable. It will be rougher and thus be more susceptible to galling because of the roughness despite the increased hardness induced by the compressive stress from the peening. Cold rolled surfaces will be harder and usually more galling resistant than machined surfaces.

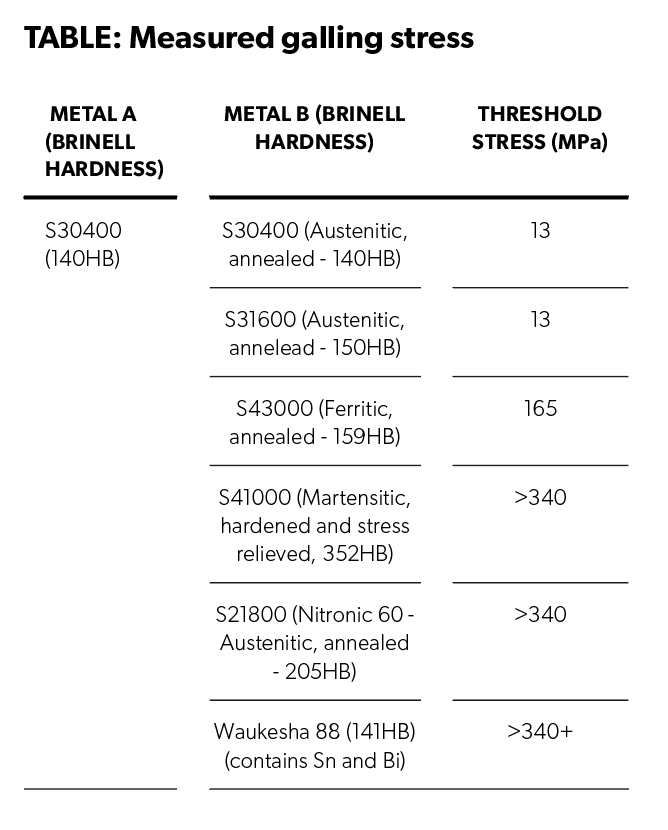

There is a rule of thumb that a hardness difference of 50 Brinell is required for effective prevention of galling and this is illustrated in the experimental data shown below.

Design and quality control

Surface finish

Highly polished surfaces (Ra <0.25 μm) or very rough surfaces (Ra <1.5 μm) tend to gall more. Cold rolled surfaces are better as they tend to be smoother than machined surfaces. Machined threads should be carefully deburred before assembly. Inspection with a low power lens (x5 or x10) is a useful control methods or, as a practical test, if a cloth snags when wiped over the thread surface, then the bolt is likely to gall when assembled. Significant galling problems may also arise with electropolished surfaces which can be very smooth, i.e. Ra <0.25 μm. However, electropolishing smooths rough edges and for this reason is an advantage in reducing galling tendency.

Goodness of fit

Parts should be dimensionally tight enough to prevent vibration and wear with consequent roughness which might facilitate galling. However, sufficient clearance is required to avoid fouling during assembly.

Quality control

Good housekeeping is needed to exclude dirt or abrasive materials from between mating surfaces. It is also vital that the thread profile match, i.e. diameter, clearance and thread form.

Reduce friction

Lubrication

There are a wide range of lubricants containing nickel, molybdenum, copper, silver or graphite, or combinations of these. They can be messy. Those primarily containing nickel are more suitable for high temperatures. Two suppliers of nickel and graphite containing anti-seize compounds are Devcon and Loctite. Their websites offer selection tables depending on service requirements. Unasco also offers both a nickel and a silver impregnated Teflon® tape. Molybdenum disulphide may also be suitable.

The graph below shows that using a lubricant makes a substantial difference to the torque value for the bolt condition.

Be aware of possible crevice corrosion between the grease and the steel if the grease dries out and cracks or, if the grease does not properly wet the surface so that a cavity forms allowing water to accumulate. If graphite is used in large quantities then galvanic corrosion of the stainless steel is possible. Nickel plating has been used as a protection against such corrosion. Silver plating has also been used as a lubricant to prevent galling of nickel-copper (Monel) alloys in oxygen service.

Material selection

If the system is not lubricated or has insufficient lubrication, proper grade selection is vital to limit galling. There can be an improvement obtained by using two different stainless steels across the interface. This is largely related to the magnitude of the hardness difference between the two steels and some experimental information is shown below. There also grades which are self-lubricating such as the high nickel grade Waukesha 88 which contains tin and bismuth or Waukesha 54C which contains tin and silver. The sulphide particles in free machining 303 also appears to provide lubrication. The corrosion resistance of these grades should be carfeully considered. In addition, some lower nickel, 200 series grades with nitrogen, manganese and silicon additions, such as ARMCO's Nitronic® 60 or Carpenter Technology's Gall-Tough® and Gall-Tough Plus®, strongly resist galling.

It should be noted that while using 304 bolts with 316 nuts is often quoted as a cure for galling, the hardness difference is not necessarily sufficient to prevent galling even with a cold rolled, harder 304 thread used against an annealed, softer 316 nut. There are reports that A2-80 and A4-80 bolts are more resistant to galling than 70 class bolts, but there are other reports that cold work increases risk. A substantial set of galling stress data is given in pages 61-65 of the 'Stainless Steel Blue Book' available from Carpenter Technology.

If an austenitic bolt such as 304 or 316 is used, then galling could be minimised by using a hard nut of duplex stainless steel or martensitic 431 stainless steel. Alternatively, a soft (also less corrosion resistant) but of aluminium bronze could be used, provided that the environment was not so corrosive that it caused rapid wastage of the aluminium bronze nut.

Surface contact stress

Reducing the surface pressure is effective in reducing the risk of galling. This may be achieved by increasing the contact area or reducing the load, so that there is less stress on parts in contact and less depth of wear. Over-tightening the bolt will give excessive surface stresses and the only way to control this is to use a torque wrench and torque appropriate to the grade of stainless steel, size, pitch and the state of lubrication.

Under-tightening is also a risk if the bolt is not clean and, if there are cyclic loads, this can lead to fatigue or even permit the nut to shake loose.

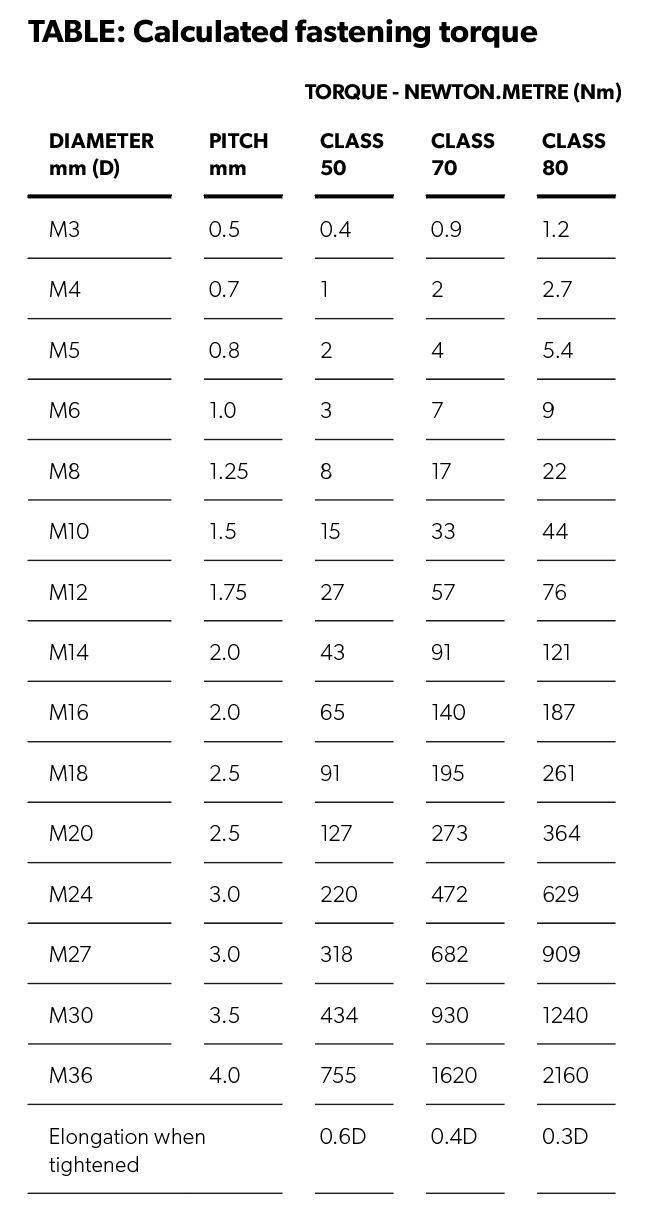

The torque table below was calculated (www.bufab.com) by assuming clean, burr-free, flat surfaces with a good quality lubricant - with a friction coefficient of 0.16. These values are only a guide and in critical applications, trials may be required. The class rating are from ISO 3506 and apply for A2 (304) and A4 (316) fasteners.

WHAT IS EXPERIMENTAL EVIDENCE?

The table below shows the results of rotating pin-on-block experiments for several material pairs (ASTM G98). It indicates the threshold stress where galling commences for different materials in contact with 304 grade stainless steel using a button and rotating block test. The hardness of the steel in Brinell hardness values is given for each material.

IMPORTANT DISCLAIMER: The technical recommendations contained in this article are necessarily of a general nature and should not be relied on for specific applications without first securing competent advice. Whilst ASSDA has taken all reasonable steps to ensure the information contained herein is accurate and current, ASSDA does not warrant the accuracy or completeness of the information and does not accept liability for errors or omissions.