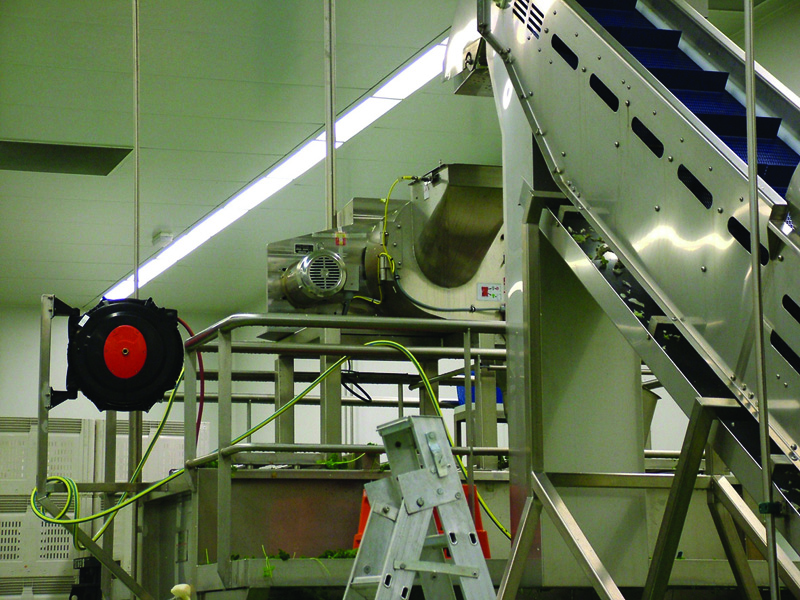

Hygiene and the 'cleanability' of equipment used in the production of food are paramount. The widespread use of stainless steel equipment in the food industry goes some way towards ensuring these criteria are met - but the assurances provided by stainless steel are only as good as the fabrication quality of the equipment.

Following a presentation at ASSDA’s annual conference in 2003 on the quality of food fabrications, particularly in the dairy industry, it became apparent that fabrication specifications, if they existed, were often inadequate and inconsistent.

As a result, ASSDA launched a co-operative venture, working closely with many fabricators

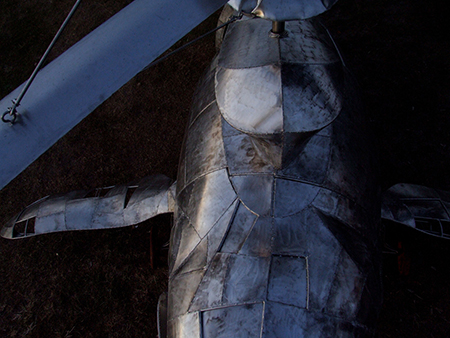

Unveiled just three days from the start of the Melbourne 2006 Commonwealth Games, the 10 sculptures are a tribute to multiculturalism.

Unveiled just three days from the start of the Melbourne 2006 Commonwealth Games, the 10 sculptures are a tribute to multiculturalism.

Bridgeman's Managing Director Len Webb said there was previously no system available

Bridgeman's Managing Director Len Webb said there was previously no system available

ASSDA member Southern Stainless typically specialises in the manufacture of stainless steel products including wine storage and fermentation tanks and marine fitouts, but supplying stainless steel barbeques, boat mounting systems and accessories to the general public, wholesalers, retailers and building industry

ASSDA member Southern Stainless typically specialises in the manufacture of stainless steel products including wine storage and fermentation tanks and marine fitouts, but supplying stainless steel barbeques, boat mounting systems and accessories to the general public, wholesalers, retailers and building industry

The staircase used 560 kilograms of grade 316 stainless steel supplied by Atlas Specialty Metals in Berrimah. Standing 4.5metres high and stretching out 3.5metres, the structure was built to complement the handrails around the pool area as well

The staircase used 560 kilograms of grade 316 stainless steel supplied by Atlas Specialty Metals in Berrimah. Standing 4.5metres high and stretching out 3.5metres, the structure was built to complement the handrails around the pool area as well

Renowned Australian sculptor Inge King AM was born in Germany in 1918, moving to Australia in 1951 and forging her career despite a culturally conservative landscape at the time.

Renowned Australian sculptor Inge King AM was born in Germany in 1918, moving to Australia in 1951 and forging her career despite a culturally conservative landscape at the time.