A stainless steel stackable wine storage and fermentation system has been adapted to carry water for use in hospitals.

STAKVATs feature internal temperature control tubes and a sloped design for complete drainage and radius corners for protection against crevice corrosion and bacteria collection.

Each vat has a storage capacity of 900 litres, can be stacked five high and easily transported on a tray truck. They are also fork-liftable four ways.

The vats are made from grade 316 stainless steel sheet and grade 304 tube. Standard BSM grade 316 fittings are used for the outlets, with door handles and locking pins

170 metres of tube was used for the staircase, which was spiralled and fixed to the mild steel structure of the building. Washers and neoprene gaskets were used to separate the stainless steel from the mild steel, avoiding corrosion issues caused by dissimilar metal contact.

170 metres of tube was used for the staircase, which was spiralled and fixed to the mild steel structure of the building. Washers and neoprene gaskets were used to separate the stainless steel from the mild steel, avoiding corrosion issues caused by dissimilar metal contact.

Designing and creating a trio of life-size sculptures has occupied much of Allen Minogue's time since his retirement as an engineer and designer.

Designing and creating a trio of life-size sculptures has occupied much of Allen Minogue's time since his retirement as an engineer and designer.

The Workshops began operations in the 1860s and initially assembled components imported from England, but by the early 1900s railway stock was being manufactured from the ground up. During the peak employment period of the 1950s there were over 3 000 workers. To reflect the Workshops’ importance in shaping the identity of the town of Ipswich, west of Brisbane, the design brief called for a monument concentrating on the social history of the Workshops

The Workshops began operations in the 1860s and initially assembled components imported from England, but by the early 1900s railway stock was being manufactured from the ground up. During the peak employment period of the 1950s there were over 3 000 workers. To reflect the Workshops’ importance in shaping the identity of the town of Ipswich, west of Brisbane, the design brief called for a monument concentrating on the social history of the Workshops

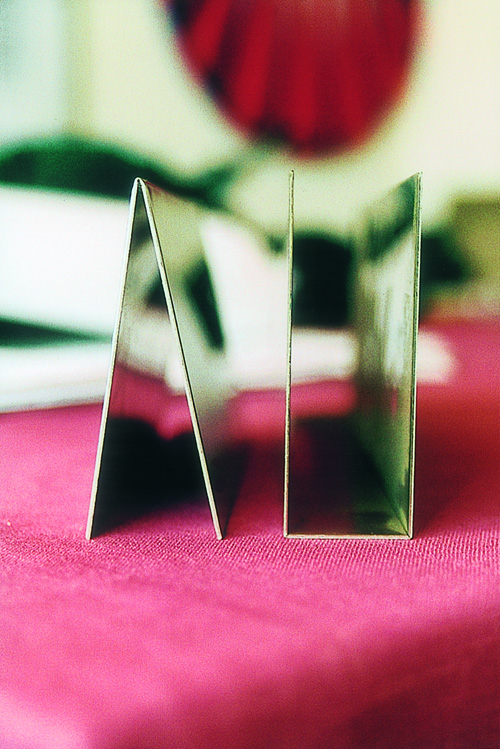

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

INSPIRED BY NATURE

INSPIRED BY NATURE

Stainless steel balustrades will preserve open views across to Southbank and back to the CBD while ensuring public safety. These combine subtly

Stainless steel balustrades will preserve open views across to Southbank and back to the CBD while ensuring public safety. These combine subtly